Form

Bulk and Custom Quotation Request

If you need a product to meet a specific quality requirement, bulk quantity or packaging formats, Please use this form to request price and lead time.

Form

Specialty Coatings

ILC Coatings specializes in custom thin film design and process development.

Our teams focus on the development of new thin film technology including obtaining unique optical and material properties and achieving precise coating applications for complex substrates.

Examples include optical coatings in the UV, visible, infrared and microwave ranges optimized for solar rejection, active/passive thermal control, atomic oxygen resistance, laser damage resistance, abrasion resistance, and environmental stability/durability, transparent conductive films, patterned films, and thin film coated textiles.

Industries Served

With decades of experience in thin film materials, processes, and characterization, we offer customers highly specialized solutions for:

- Aerospace and Defense

- Commercial

- Biomedical

- Scientific Research Industries

Core Capabilities

- New thin film technology

- Full-scale testing, inspection, and analysis

- Instrumentation including spectrophotometry and interferometry

- Substrate handling and fabrication

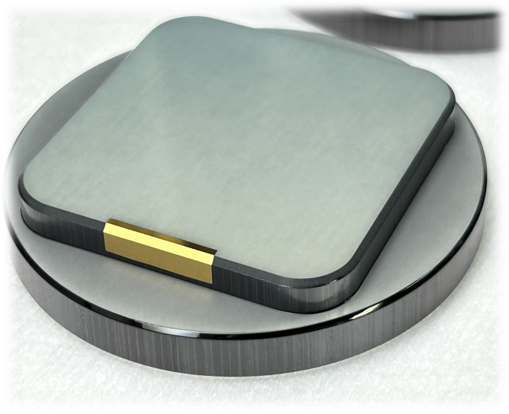

Specialized Thin Films for Complex Substrates

Our technology provides precise coating application to complex 3-dimensional substrates, structured materials, and even thin film pigment. Designs include broad band anti-reflection, high reflectors, metal/protected metal coatings, enhanced metal coatings, neutral density filters, cold/hot mirrors, edge/bandpass filters, spike filters, dichroic mirrors, filters, beam splitters, as well as electro-optical devices.

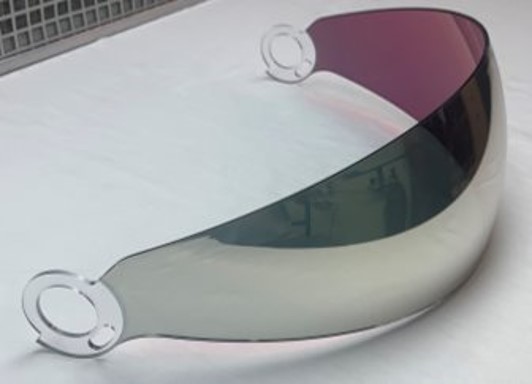

Pioneering Space Safety: Over Two Decades of Advanced Coating Technology on International Space Station Spacesuits

ILC Coatings has applied the Advanced Thermal Control Coating (DRLI-ATCC) and Advanced Solar Control Coating (DRLI-ASCC) to the ISS Spacesuit helmet and visor assembly since 1997.